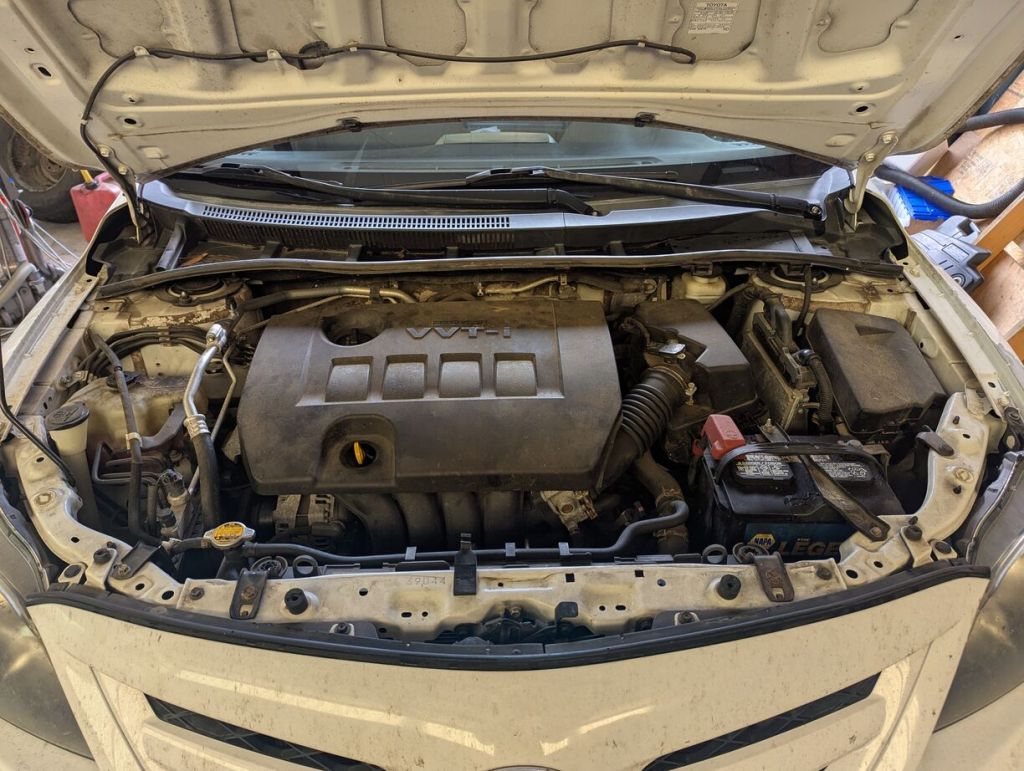

![terminal screen with system info: jason@desktop:~$ screenfetch | lolcat

_,met$$$$$gg. jason@desktop

,g$$$$$$$$$$$$$$$P. OS: Debian 12 bookworm

,g$$P"" """Y$$.". Kernel: x86_64 Linux 6.12.32+bpo-amd64

,$$P' `$$$. Uptime: 10h 8m

',$$P ,ggs. `$$b: Packages: 2323

`d$$' ,$P"' . $$$ Shell: bash 5.2.15

$$P d$' , $$P Resolution: 1920x1080

$$: $$. - ,d$$' DE: Xfce

$$\; Y$b._ _,d$P' WM: Xfwm4

Y$$. `.`"Y$$$$P"' WM Theme: Haiku-Alpha

`$$b "-.__ GTK Theme: BeOS-r5-GTK-master [GTK2]

`Y$$ Icon Theme: BeOS-r5-Icons-master

`Y$$. Font: Swis721 BT 9

`$$b. Disk: 7.7T / 11T (75%)

`Y$$b. CPU: AMD Ryzen 7 7700 8-Core @ 16x 5.389GHz

`"Y$b._ GPU: NVIDIA GeForce RTX 3090, NVIDIA RTX A4000, NVIDIA RTX A4000, NVIDIA RTX A4000

`"""" RAM: 9486MiB / 63916MiB](https://dynamicsubspace.net/wp-content/uploads/2025/07/system-info-debian-kernel-612.png?w=832)

If you’re like me, you might have newer computer hardware that isn’t fully supported by Linux kernel 6.1, which is installed with Debian Bookworm 12. Thankfully, Debian offers Backports, or newer software in testing in Trixie, the development name for Debian 13, that will eventually find its way into future Debian releases for use on an otherwise stable release of Bookworm.

Updating to a newer kernel often brings more hardware compatibility. However, it’s important to remember that using a backport kernel can introduce potential compatibility issues with the software officially supported on Bookworm. Even if installing the latest kernel causes some issues, you can choose to boot from one of your older 6.1 kernels on your install as long as you don’t delete them (by using the apt autoremove command).

I wrote this guide based on my experience installing Linux kernel 6.12 from Backports with the non-free firmware that my hardware needs to work. If you are trying to keep your system free from non-free software, you can omit those references in the instructions below.

Before doing any changes to your Debian installation, remember to backup your files first. Saving important files in more than one media and storing it backups in different physical locations is best practice.

After backing up your files, make sure your install is up-to-date with these commands:

sudo apt update

sudo apt upgradeAfter those updates complete, it’s a good rule of thumb to do a reboot to begin working with a clean slate.

Next, add Debian Backports to /etc/apt sources.list. I used vi to do this:

sudo vi /etc/apt/sources.listIn vi, arrow down to the bottom line, type a lowercase “o” to add a blank line below the current line, type lowercase “i” to enter input mode, and type the following line into the document:

deb http://deb.debian.org/debian bookworm-backports main contrib non-free non-free-firmwareAfter double checking the added line, press the “Esc” key, and type “:wq” to write the file and quit vi.

Now, you need to update apt again:

sudo apt updateAfter the completes, enter this command to install the latest kernel from backports along with the kernel’s headers and firmware that might be needed for your hardware (such as networking card, video card drivers, etc.).

sudo apt install -t bookworm-backports linux-image-amd64 linux-headers-amd64 firmware-misc-nonfreeIt might take awhile for the installation to complete. If there are no errors, it should return you to your terminal prompt. If it did, reboot your computer to load the new kernel.

After your computer boots up again, you can verify that you are running the latest kernel by entering this command:

uname -rAfter installing the latest kernel, my computer reports this from the uname -r command:

6.12.32+bpo-amd64